Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

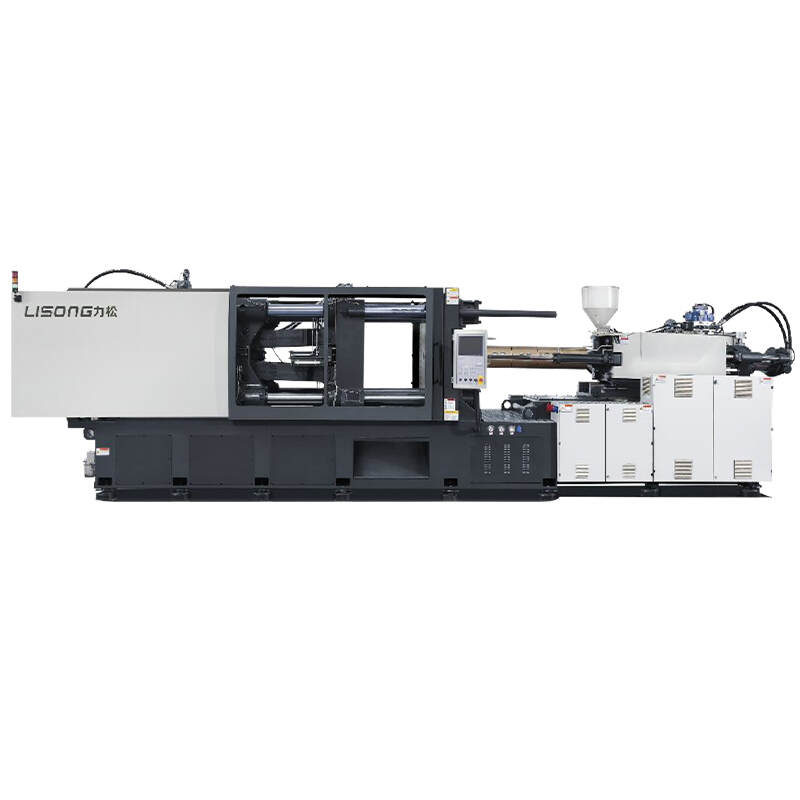

CAP INJECTION MACHINE

This machine adopts motor-driven hydraulic to quickly rotate the cold runner, and cooperates with the hydraulic system to realize high-speed operation, which meets the high-speed filling requirements of soda and water. For the production of caps for pharmaceutical bottles and caps for filling soft drinks, can be designed as wide-mouth bottles and narrow-mouth bottles. The machine has a set of plastic molds. Each mold can hold a different bottle and can produce many different shapes.

Produce Details

Place of Origin: China

Brand Name: LISONG

Certification: CE

Payment & Shipping Terms

Minimum Order Quantity:1 set

Packaging Details:container&car

Delivery Time:60 days

Payments: T/T LC

specification

|

|

LS170K |

LS220K |

LS290K |

LS600K |

|

Screw Diameter:

|

40mm |

45mm |

55mm |

80mm |

|

Screw L/D Ratio: |

22.5L/D

|

22.5L/D

|

21.8L/D

|

22L/D |

|

Shot Volume: |

253cm³ |

334cm³ |

618cm³ |

2212cm³ |

|

Shot weight: |

230G |

304G |

562G |

2013G |

|

injection Rate: |

117g/s |

148g/s |

215g/s |

448g/s |

|

Injection Speed: |

366mm/s

|

332mm/s |

396mm/s |

516mm/s |

|

injection Pressure: |

215Mpa

|

210Mpa |

219Mpa |

180Mpa |

|

Screw Speed: |

205Rpm

|

180Rpm |

215Rpm |

135Rpm |

Product Features

1. The machine consists of two precision linear guide rails installed on two guide shafts and a two-station heating trolley that moves along the guide rails.

2. The design is simple and the external material is strong, so the machine produces less noise.

3. Holds 1 oz, 4 oz, 16 oz and 32 oz. container.

4. Equipped with an automatic mode switch, the operator can quickly and easily change the size of the bottle without manually changing the settings on the machine.

5.Including rack-mounted metering machine and pump. Caps are loaded directly into the machine from the secondary bag and held in place by a clamping system that does not interfere with the process.

6.Equipped with a variable speed control mechanism, which enables users to accurately control the injection time.

Product Advantages

1. Technical: Hot runner molding method and multi-directional cooling system are adopted, and new high-temperature flow technology is used to rapidly cool the heat to meet the requirements of parts.

2. Adaptability: The machine is designed to allow quick replacement of different caps, even cap suppliers

3. Convenience: Special design makes it easy to use and clean.

Applications

Small volume packaging and bottling applications.

wine or restaurant application.

Mass production applications, ensuring good product quality and minimizing product waste.